Are you experiencing an increased rate of returns? Did the product arrive late, and the vendor struggled to explain why with excuses? Is the order process taking much longer than you initially projected? We encounter many problems every day while trying to run a lean and agile fashion business.

Everyone in the Fashion industry is going at 100 miles per hour and often reacts to the challenges trying to solve the symptom, not the root cause. However, we all know that being reactive instead of proactively improving processes and permanently solving the root of the bottleneck that causes long lead times and costs your company money won’t get you very far. Your team might feel a temporary relief with some solutions in place, but if we don’t address the root cause, the challenge will come back and might damage the business in the long run.

Often, consultants need to come in when we try to optimize LEAN operations and solve the bottlenecks that cause delays. Their job is to assess the challenges and provide a fresh 3rd party perspective to help the team ask the right questions and support uncovering the underlying problem. Teams – process users tend to focus on solving the symptom as a reaction to the problem occurs.

Like the fire, when it flames up, the first reaction is to pour water to stop the fire from spreading. Often, they do not have time or energy to pause and dig into the root cause of why that fire started in the first place.

Most of the time, the teams will put the fire out, repair the damage that accrued and move on, while the root cause is still left unresolved, and another fire is most likely to occur with time. The management team must force the pause and dig deeper into the reasons why it happened in the first place. While consultants can certainly help with their extensive knowledge and training on the subject, you don’t necessarily have to wait for somebody to teach your team basic principles and essential tools of lean to start benefiting from it.

Many tools can help with determining the root cause of the problem. We want to share one of the most effective and often practiced tools – “5 WHYS?”

5 WHYS is one the easiest and fundamentally essential tools we use in Lean Management. It is often the case that when we do things, things go wrong. It’s normal, and if things don’t go wrong, something is not standard with that setup. The supervisor/ manager must resolve the issue and set things right as quickly as possible when things go wrong.

However, it is equally important to understand why the mistake or bottleneck happened and take necessary measures to eliminate or drastically reduce the recurrence of the same issue again. In management studies & LEAN, we called this procedure Root Cause Analysis. It sounds complicated, but it is nothing but digging into the issue and understanding why it happened.

What are the 5 Whys?

Five whys (5 whys) is a problem-solving method that explores the underlying cause-and-effect of particular problems.

It is simply asking WHY, WHY, WHY, WHY, WHY, and chances are when you are in your fifth why, you should be beginning to understand WHY things went wrong. But in any means, 5 WHYS don’t limit your questioning of whys to just five times, though often five times is enough to figure out the issue.

The primary goal is to determine the root cause of a defect or a problem by successively asking the question, “Why?”. The number ‘5’ here comes from the anecdotal observation that five iterations of asking why is usually sufficient to reveal the root cause.

In some cases, it may take more or fewer whys, depending on the depth of the root cause.

Why The Five Whys?

The main benefit of the Five Whys is that it is one of the most powerful assessment methods of all non-statistical analyses. It can uncover and trace back to problems that were not obvious.

It is simple, and it works.

The Benefits of Five Whys

-

- It helps identify the root cause of a problem.

- Understand how one process can cause a chain of problems

- Determine the relationship between different root causes

- Highly effective without complicated evaluation techniques

Five Whys Example

Problem Return rate increased by 10%.

Why? Customer returns as the new product fits too tight.

Why? The new styles last shipment landed out of tolerance by 3% in width.

Why? Landed shipment does not match the TOP (Top of the Production samples) spec, which was with intolerance.

Why? Product shrinks more during shipment.

Why? The cutter did not relax the fabric overnight after spreading it on the cutting table.

Here’s an example of how this works. In the example above, we can see that the original problem of the increased return rate directly correlates with the failure of the process on the manufacturing floor. If the team did not ask the 5 Whys, they most likely would have discounted the product with the poor fit to sell through, cut the losses, charged back, and stopped working with factory X.

However, with now knowing the root cause, the team can address the failure of the process with the factory, add a clause in the manufacturing agreement that will protect them from this type of mistake in the future with possible chargebacks in place, and set control points for the audit team to assure quality and fit in the future shipments.

They can salvage the vendor relationship and build a stronger partnership with the manufacturer that will go the extra mile for them in the future. The Root Cause reveals the source of the problem. By coming up with a solution for the root cause, there is a high chance that all of the whys leading up to the final answer will naturally get resolved.

When Should You Use This Method?

-

- For simple to moderately complex problems

- More complex problems may require this method in combination with some others.

- When problems involve human factors or interactions, human error is involved in the process at any time.

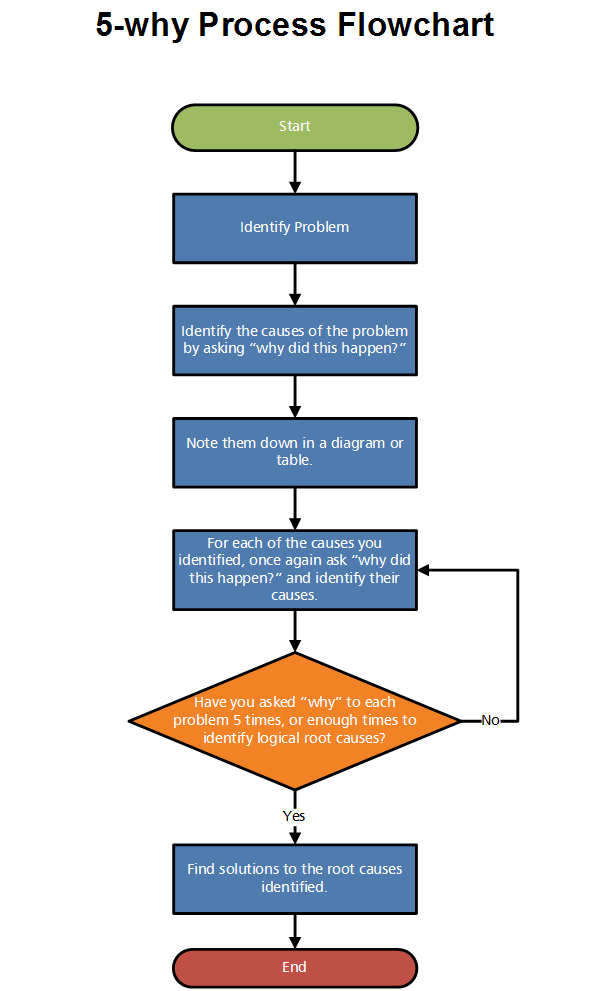

How to Complete a Five Whys Root Cause Analysis

-

- Begin with a specific problem. What is it that you are having an issue with? This can also help the team focus on the same problem.

- Ask why the problem happened and write the answer below the specific problem you listed in step one.

- Keep asking “why” to each of the straight answers you write down until you reach the root cause of the problem.

- Again, this may take more or less than five “why”s. Make sure your team sees eye-to-eye with each of the questions being answered and the final root cause.

Essential Things to Keep in Mind

-

- Distinguish causes from symptoms or causal factors

- To make sure that you are attributing the correct answer to each “why,” try working backward. (Answer to the “Why?” + “and therefore” + the Problem Identified for that Question)

- You can break down your answers as much as you like. The more, the better.

- Answers should always be based on facts and data.

- Last but not least, assess the process, not the people.

Five Whys Tools

The simplest way of conducting the Five Whys test is to write it down on paper. However, the fishbone, or the Ishikawa diagram, can help during the initial process of identifying problems. The diagram can reveal problems that may need the five whys for a deeper look. Then, you can gather all of the root-cause-effect relationships and evaluate which of them had the most significant impact on the original problem.