Think “Lean” when creating an assortment for next year and apply the 80:20 rule to drive continuous assortment improvement. For lean assortment planning…

IDENTIFY WHAT HAS WORKED AND IDENTIFY WHAT TO CARRY OVER, EXPAND ON, AND ONLY THEN DESIGN NEW.

To begin designing your next collection, the first thing to consider is to analyze the past few years of sales data, if available. If you are just starting, you will need to research what your competitors have sold well in the past few years and what went on clearance at the end of the season. Luckily, with the power of the internet and social media, we can backtrack some of that information by searching the collections, customer feedback on the design, and product in the clearance sections to draw our initial conclusions.

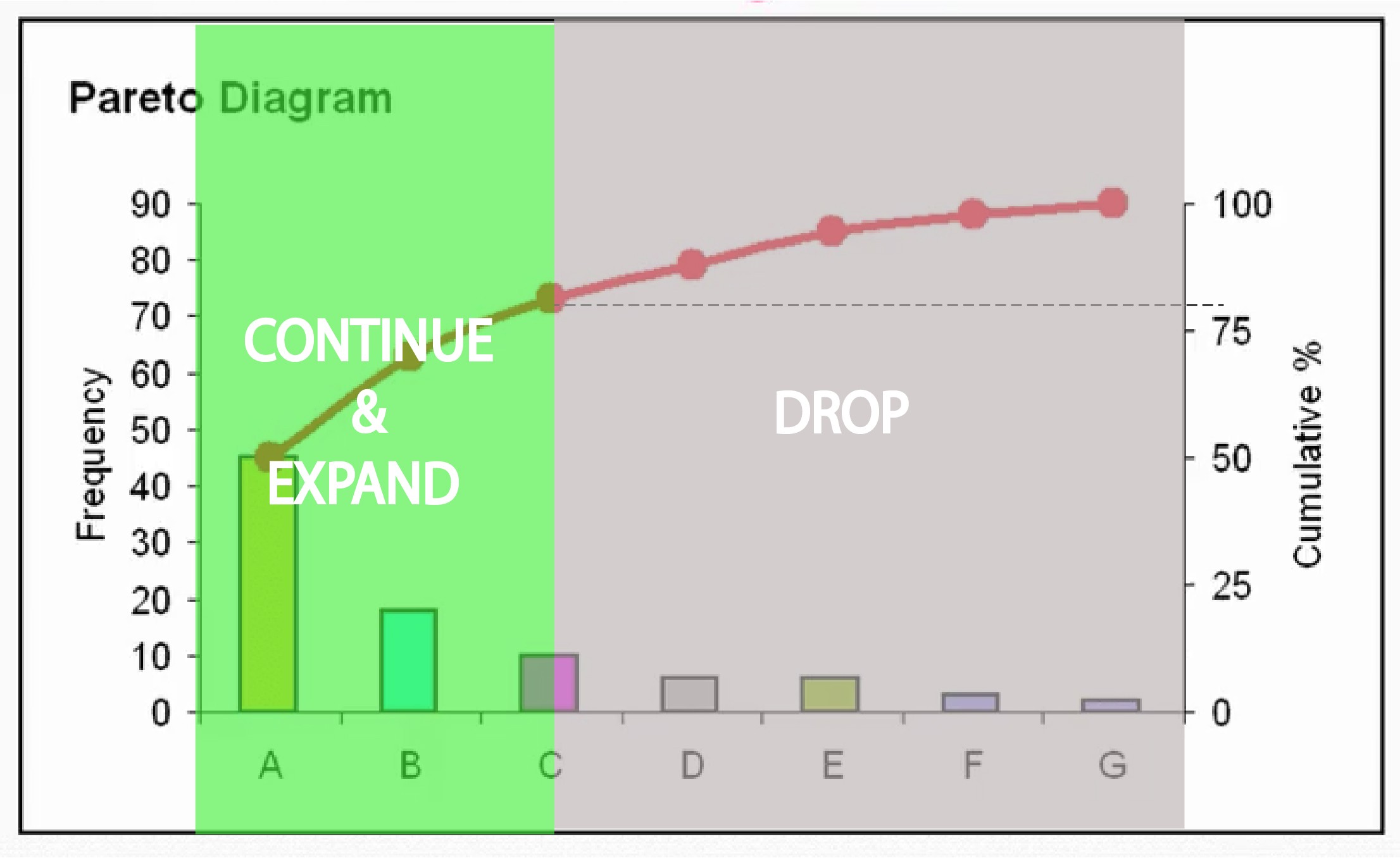

There are a few effective ways to identify what to carry over, what to expand on, and what not to design using an 80/20 Pareto Analysis. Commonly referred to as the 80/20 rule, it is the foundation to reveal the opportunities for optimized assortment or a process.

To identify what 20% of your assortment drives 80% of your sales, you need to key in on what styles and product characteristics like fabric or color continue to perform and generate the most sales for your brand. If you have past sales data, you have a tremendous opportunity to learn from it and make more strategic decisions for the following collection.

Look at products sold by product category, products sold by color, products sold by body style, products sold by fabrication, and new product vs. carryover styles sales. Apply an 80/20 rule analysis to the collected data and capture the highest-performing product and its characteristics. With this simple tool, you can identify the proper ratio of carryover styles to new designs and focus your following assortment toward products that generate higher sales velocity with less variation of product offerings, which will help to increase profitability in the long run.

Assortment planning and deciding what to keep, expand, or drop can be overwhelming. Often my clients struggle to find the balance between what to carry over and how much to bring in new designs.

In the example of our work for a client in the sports licensing space, the ultimate ratio was to carry over 60% of the styles and expand them into new color variations while reserving 40% for the new graphics and new silhouettes.

However, even the new styles were designed into already existing fabric groups to assure maximum use of each fabrication and manufacturing vendor’s capabilities which helped to increase the volume of units per fabrication and allowed us to negotiate the better cost and increase product margins.

To determine which fabrications performed the most and what styles and graphics were essential to carry over, we applied an 80:20 rule. We analyzed three years of sales data to identify what 20 percent of the styles had been generating 80 percent of sales. Rest assured, we found the winning styles. The rest was variations that tied up the money in inventory. Once we identified what performed, we sold off the rest, opening the budget to bring newness, keeping in mind the new guidelines we have set.

Most importantly, this method could trim down the number of vendors we had to manage the product from. When we narrowed the number of manufacturing partners by 60% and left the ones whose products performed, we were able to optimize the supply chain and ease the workload of the merchandising and product development team, increasing their performance efficiency.

We love to hear your thoughts and what has worked for you! Drop a comment below.